Ceramic Ring Partitioned

Ceramic Cross Partition Ring is a packing designed basically from the Raschig Ring with the cross-partitions inside to increase the surface. And enhance the transfer efficiency. Ceramic Cross Partition Rings are available to the order.Our range of products is manufactured according to the needs of our client. In order to maintain flawless production, we have a team of qualified and well versed professionals.

Ceramic Ring Partitioned represents the pinnacle of advanced materials, where innovation converges with purpose. As you navigate our virtual space, discover the intricacies of partitioned ceramic rings, a solution meticulously crafted to cater to diverse industries, from high-tech electronics to precision machinery and more. As a trusted ceramic ring partitioned manufacturer in India, we provide comprehensive resources and insights into the myriad applications where these rings excel.

| Size(Nominal) | - | 25 x 25 x 3 | 35 x 35 x 3 | 50 x 50 x 6 | 80 x 80 x 8 | 100 x 100 x 10 | 150 x 150 x 15 |

|

Diameter D mm

|

- | 25 ± 2 | 35 ± 2 | 50 ± 3 | 80 ± 4 | 100 ± 5 | 150 ± 5 |

|

Length L mm

|

- | 25 ± 2 | 35 ± 2 | 50 ± 3 | 80 ± 4 | 100 ± 5 | 150 ± 5 |

|

Thickness T mm

|

- | 3 ± 1 | 4 ± 1 | 6 ± 2 | 8 ± 2 | 10 ± 2 | 15 ± 5 |

|

Quantity(Aprx ±10%) Nos. per cubic meter

|

Dumped Stacked | 440000 - |

16250 - |

5700 7000 |

- 1720 |

- 730 |

- 280 |

|

Weight (Aprx ± 10%) Kg per cubic meter

|

Dumped Stacked | 713 - |

650 - |

655 804 |

- 774 |

- 694 |

- 617 |

| % Free space (Aprx) | Dumped Stacked | 67 - |

71 - |

72 63 |

- 68 |

- 76 |

- 62 |

| Contact surface M2/M3 (Aprx ) | Dumped Stacked | 232 - |

165 - |

112 138 |

- 89 |

- 64 |

- 48 |

| Relative efficiency M2/M3 of free space | Dumped Stacked | 346 - |

232 - |

156 219 |

- 131 |

- 84 |

- 77 |

| Relative scrubbing capacity M2/M3 Free space | Dumped Stacked | 155 - |

117 - |

81 87 |

- 61 |

- 49 |

- 30 |

Key Features

Increased Surface Area Due to Internal Partitions:

Unique design with internal divisions significantly boosts available surface areaEnhanced geometry offers more contact points for gas-liquid interactions.

Excellent Chemical Resistance:

Manufactured from high-quality ceramic materials.Withstands a wide range of corrosive chemicals, acids, and bases.

Suitable for diverse and aggressive chemical environments.

High Thermal Stability:

Maintains structural integrity and performance across a broad temperature spectrum.Effective from cryogenic conditions to high-heat applications.

Low Pressure Drop:

Design minimizes resistance to gas and liquid flow.Results in a lower pressure drop across the packed column, enhancing system efficiency.

Improved Liquid Distribution:

Partitioned structure promotes even liquid distribution throughout the packing.Reduces the risk of channeling and ensures optimal gas-liquid contact.

Enhanced Mass Transfer Efficiency:

Combination of increased surface area and improved liquid distribution.Leads to superior mass transfer efficiency, enhancing separation and reaction processes.

Benefits:

Higher Column Efficiency:

More effective use of column space.Better separation or reaction outcomes within the same column dimensions.

Reduced Energy Consumption:

Lower pressure drop means less energy required to move fluids.Significant operational cost savings over time.

Extended Equipment Life:

Excellent chemical resistance protects columns and equipment from corrosive damage.Reduces maintenance needs and extends operational life.

Minimized Channeling and Improved Wetting:

Prevents liquid from taking preferential paths through the packing.Ensures uniform and efficient gas-liquid contact.

Versatility in Operating Conditions:

High chemical and thermal resistance.Suitable for various processes and industries, from petrochemical to environmental applications.

Cost-Effective Solution:

Improved efficiency and longevity result in lower total cost of ownership over time.Product Variations:

Size Options:

1-inch (25 mm): Ideal for smaller diameter columns or higher packing density.1.5-inch (38 mm): Versatile mid-size option for a wide range of applications.

2-inch (50 mm): Balances surface area and void space for medium to large columns.,

3-inch (76 mm): Best for larger diameter columns, providing lower pressure drop in high-flow applications.

Material Options::

Standard Ceramic: Suitable for most general applications, balancing performance and cost.High-Alumina Ceramic: Enhanced chemical resistance for highly corrosive environments.

Custom Formulations: Available upon request for specific process requirements or unusual operating conditions.

The variety of sizes and materials ensures optimal packing performance tailored to your unique process needs.

Applications:

Distillation columnsAbsorption towers

Stripping columns

Scrubbers

Chemical reactors

Gas-liquid contactors

Wastewater treatment plants

Petrochemical processes

Why Choose Us

Customization: Our products are designed to meet specific requirements, ensuring a perfect fit for every project.

Quality Assurance: We maintain the highest quality standards to provide durable and reliable ceramic partitions.

Customer-Centric Approach:We prioritize customer satisfaction and offer responsive support throughout your project.

Innovation: Keeping up with the latest advancements in ceramic technology to offer cutting-edge solutions.

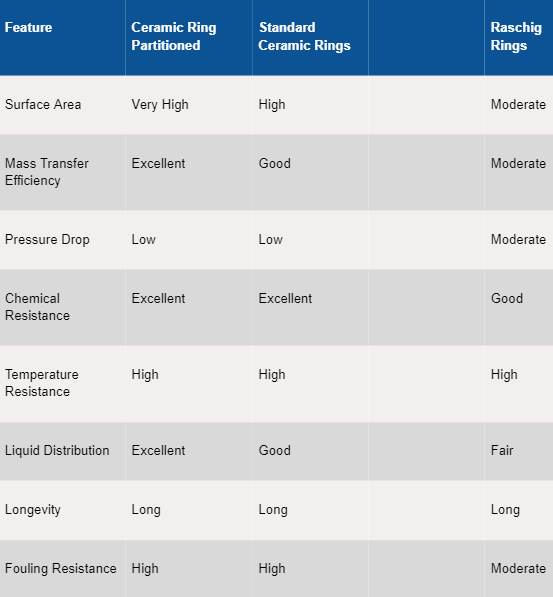

Comparison Table:

FAQ'S