Ceramic Saddles

Ideally, ceramic saddles are used to ensure efficient mass transfer and low-pressure drop. They are also good for distillation especially when one is working with acids. They are made from the porcelain chemical and therefore, have a high resistance to all acids.We are offering a wide range of industrial ceramic saddles, which are fired at high temperatures and have excellent mechanical, abrasion, and heat resistance.

Explore the versatility of ceramic saddles as we delve into their superior geometric shape, durability, and resistance to harsh environments. Whether you are seeking solutions for distillation, absorption, or stripping applications.our comprehensive information hub will guide you through the features that set ceramic saddles apart in the world of packing materials.

As you navigate through our virtual space, you will unravel the myriad benefits and applications that make ceramic saddles an indispensable choice for optimizing processes and enhancing productivity. our ceramic saddles empower your operations with reliability, longevity, and performance.

| Size MM(Nominal) | 12 mm | 19 mm | 25 mm | 38 mm | 50mm |

|

A

|

on request | 26 ± 2.6 | 34 ± 3 | 51 ± 3 | 68 ± 4 |

|

B

|

on request | 18 ± 1.8 | 24 ± 2 | 35 ± 2 | 47 ± 2.8 |

|

C

|

on request | 13 ± 1.3 | 17 ± 2 | 25.5 ± 2 | 34 ± 3 |

|

D

|

on request | 10.5 ± 1 | 14 ± 1 | 22 ± 1 | 30 ± 1.8 |

|

E

|

on request | 2.5 ± 0.25 | 3.5 ± 0.5 | 4.5 ± 0.5 | 6 ± 1 |

| Quantity (Aprx ±10%) Nos. per cubic meter | on request | 162500 | 70000 | 21000 | 9300 |

| Weight(Aprx±10%) Kg per cubic meter | on request | 593 | 586 | 594 | 560 |

| % Free space (Aprx) | on request | 71 | 77 | 80 | 79 |

| Contact surface M2/M3 (Aprx) | on request | 239 | 199 | 139 | 108 |

| Relative efiiciency M2/M3 free space | on request | 337 | 258 | 174 | 137 |

| Relative scrubbing capacity M2/M3X Free space | on request | 170 | 153 | 111 | 85 |

| Packing Factor | 110 | 98 | 52 | 40 |

Key Features

Excellent Thermal Stability: These saddles maintain their structural integrity and performance across a broad temperature range, from cryogenic conditions to high-heat applications.

Low Pressure Drop: The unique design minimizes resistance to gas and liquid flow, reducing energy requirements for pumping and improving overall system efficiency.

Large Specific Surface Area: The saddle shape provides an expansive surface area per unit volume, enhancing mass transfer efficiency in separation processes.

Uniform Liquid Distribution: The geometry promotes even liquid distribution throughout the packing, preventing channeling and ensuring optimal contact between gas and liquid phases.

Benefits

Chemical Durability: They are highly resistant to chemical corrosion, ensuring longevity and efficiency in harsh chemical environments.

Excellent Surface Area: Their unique shape provides a high surface area, which improves mass transfer efficiency in packed towers.

Low Pressure Drop: Ceramic saddles facilitate smooth fluid flow, resulting in a lower pressure drop and improved process efficiency.

Mechanical Strength: They are robust and capable of withstanding significant mechanical stress, ensuring reliable performance over time.

Technical Specifications

Shape and Design: Saddle shape optimized for superior surface area and fluid distribution.

Dimensions: Available in various sizes, including small, medium, and large, to suit different reactor sizes.

Temperature Resistance: Can withstand temperatures ranging from -20°C to 1200°C.

Chemical Resistance: Resistant to most acids, alkalis, and corrosive substances.

Density: Low density for easy handling yet highly durable.

Product Variations

Applications:

2. Absorption towers

3. Stripping columns

4. Scrubbers

6. Gas-liquid contactors

7.Wastewater treatment plants

8. Flue gas desulfurization units

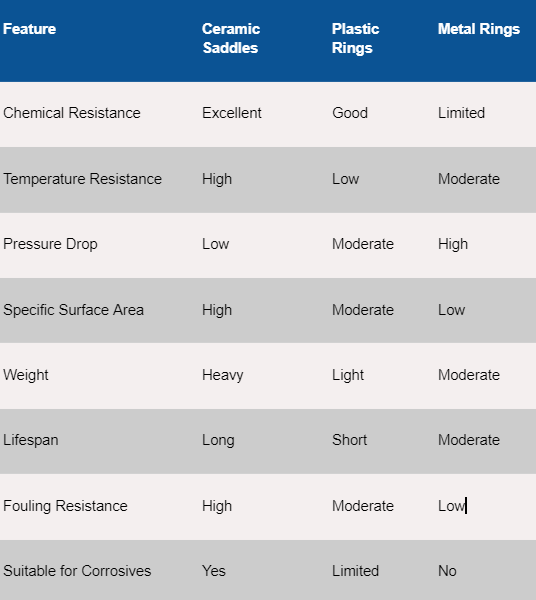

Comparison Table:

FAQ'S