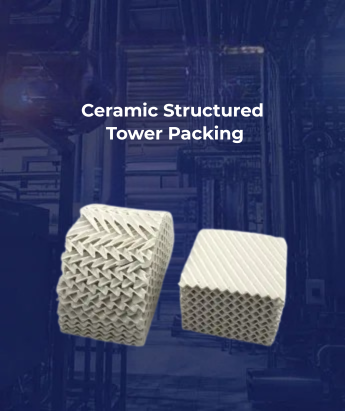

Ceramic Structured Tower Packing

Ceramic Structured Tower Packing is designed with precision to enhance efficiency in chemical and industrial applications. Made from corrugated ceramic sheets arranged in a structured pattern, this packing forms cylindrical units that deliver superior mass transfer performance. Compared to random packing, it offers lower pressure drop, higher separation efficiency, and greater liquid handling capacity, making it a trusted choice for companies seeking reliability in demanding process environments.

As a leading Ceramic Structured Tower Packing manufacturer , SKJ Group ensures products that meet international standards of durability and efficiency. This packing type is widely preferred for its excellent thermal stability, resistance to chemical corrosion, and ability to improve tower operations. Whether used in distillation, absorption, or stripping processes, Ceramic Structured Tower Packing provides long-term performance and consistent results for industries around the world.

Applications of Ceramic Structured Tower Packing

Ceramic Structured Tower Packing finds wide applications across industries that demand durability, precision, and efficiency. It is extensively used in sectors such as mining, ceramics, chemical processing, and abrasives, thanks to its ability to handle harsh operating conditions.

1. Grinding media for ball mills and grinding mills – Its structured design ensures consistent performance and long-lasting efficiency.

2. Catalyst support in chemical reactions – As a reliable Ceramic Structured Tower Packing supplier and exporter, SKJ Group delivers solutions that enhance reaction stability and productivity.

3. Structural components in industrial processes – Its high thermal and chemical resistance make it a trusted choice for demanding process environments.

Advantages of Ceramic Structured Tower Packing

Features of Ceramic Structured Tower Packing

Why Choose Ceramic Structured Tower Packing?

Choosing Ceramic Structured Tower Packing means investing in reliability, efficiency, and long-term value. Its unique design delivers higher separation performance, low-pressure drop, and excellent resistance to heat and chemical corrosion, making it a preferred solution for critical industrial operations.

As a trusted Ceramic Structured Tower Packing supplier in Mandsaur, SKJ Group India provides products engineered to meet international standards. With proven durability and versatility, this packing ensures optimized performance for industries ranging from chemical processing to environmental applications.

Specifications

Material – High-quality ceramic engineered for durability, thermal stability, and chemical resistance. Shape – Structured corrugated design that ensures maximum surface area and efficient mass transfer. Sizes – Available in multiple standard and customized dimensions to suit diverse tower requirements. Color Options – Offered in neutral shades with customization available to match industrial setups. Compliance – Manufactured in line with international quality and safety standards, ensuring reliable performance.FAQ’s about Ceramic Structured Tower Packing

What is Ceramic Structured Tower Packing?

What are the advantages of using Ceramic Structured Tower Packing?

What industries can benefit from using SKJ Group’s Ceramic Structured Tower Packing?

Can Ceramic Structured Tower Packing be customized to meet specific requirements?

How should Ceramic Structured Tower Packing be installed and maintained?

Is SKJ Group’s Ceramic Structured Tower Packing environmentally friendly?

What quality certifications does SKJ Group hold for its Ceramic Structured Tower Packing?