What Are Ceramic Saddles Used For?

How Cecebe HP Porcelain Saddles Enhance Performance in Packed Towers

December 11, 2024

What Are Alumina Ceramic Balls?

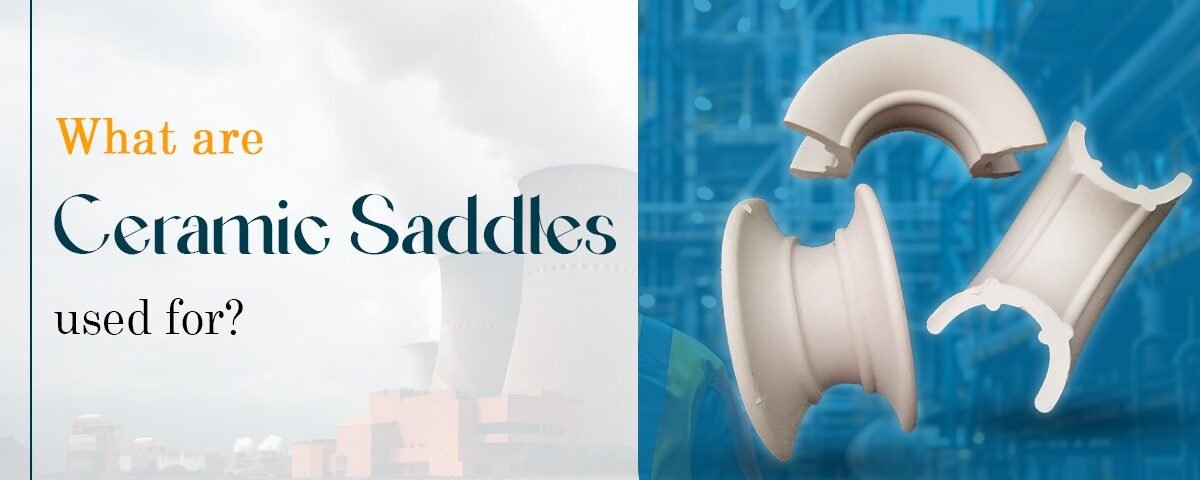

January 3, 2025Ceramic saddles are specially designed packing materials used in industrial towers to enhance gas-liquid contact, reduce pressure drop, and improve overall process efficiency. Ideal for chemical, petrochemical, and environmental applications, these ceramic saddles offer superior chemical resistance and long-lasting performance. Reliable suppliers and manufacturers provide high-quality ceramic saddles that optimize industrial operations and minimize maintenance costs.

Ceramic saddles play a vital role in industries where efficient mass transfer and robust support materials are required. If you’re involved in chemical processing, oil refining, or environmental management, you might wonder: What makes ceramic saddles indispensable? And more importantly, how can they improve your processes? This guide will answer these questions and more, offering valuable insights into the applications, benefits, and expertise of top manufacturers, suppliers, and exporters like SKJ Group.

Understanding Ceramic Saddles

Ceramic saddles are specialized packing materials commonly used in chemical engineering and industrial processes. They are designed with a curved saddle shape, maximizing surface area while minimizing pressure drop. Their primary function is to provide efficient mass transfer in packed columns, making them ideal for applications like distillation, absorption, and extraction.

Key Features of Ceramic Saddles:

- High thermal stability: They can withstand extreme temperatures without degrading.

- Chemical resistance: Non-reactive with most acids, alkalis, and solvents.

- Low pressure drop: Their design ensures minimal resistance to gas and liquid flow.

- High mechanical strength: Ideal for demanding environments.

Applications of Ceramic Saddles

1. Chemical Processing

In the chemical industry, ceramic saddles are used in packed towers for processes such as:

- Distillation: Efficient separation of liquid mixtures.

- Absorption: Capturing gases into liquids, such as in gas scrubbers.

- Desorption: Releasing gases from liquids in applications like stripping columns.

Ceramic saddles’ durability ensures long service life in these demanding applications.

2. Oil and Gas Refining

Packed columns with ceramic saddles are integral to refining processes, where they are used for:

- Removing impurities from crude oil.

- Facilitating catalytic reactions in reactors.

Their resistance to thermal shock makes them reliable under fluctuating temperature conditions.

3. Environmental Management

Ceramic saddles find extensive use in environmental applications such as:

- Gas scrubbing systems: Removing pollutants like sulfur dioxide (SO₂).

- Water treatment: Enhancing biological treatment processes.

By providing a large surface area for reactions, they optimize mass transfer efficiency in these systems.

4. Petrochemical Industry

In petrochemical plants, ceramic saddles are employed in:

- Recovery of valuable hydrocarbons.

- Treatment of byproducts to meet environmental regulations.

Why Choose Ceramic Saddles from SKJ Group?

When selecting a ceramic saddles manufacturer, quality, expertise, and reliability are paramount. SKJ Group stands out as a leading ceramic saddles supplier and exporter due to its commitment to innovation and customer satisfaction.

Advantages of SKJ Group’s Ceramic Saddles:

- Superior Quality: Manufactured with high-grade raw materials, ensuring durability and performance.

- Customization: Tailored solutions to meet specific industrial requirements.

- Global Reach: As a trusted exporter, SKJ Group delivers products to clients worldwide.

- Eco-Friendly Practices: Commitment to sustainable manufacturing processes.

Real-World Example:

A leading chemical plant partnered with SKJ Group to replace outdated tower packing with advanced ceramic saddles. The result? Improved efficiency, reduced maintenance costs, and a significant boost in productivity.

Benefits of Using Ceramic Saddles

1. Enhanced Efficiency

Ceramic saddles provide an optimal surface area for interaction between gases and liquids, maximizing process efficiency.

2. Cost Savings

With their long service life and minimal maintenance requirements, ceramic saddles reduce operational costs.

3. Environmental Compliance

Their role in pollution control systems helps industries meet stringent environmental regulations.

4. Versatility

Applicable across diverse industries, ceramic saddles offer a one-size-fits-all solution for various mass transfer challenges.

How to Choose the Right Ceramic Saddles

When selecting ceramic saddles for your operation, consider the following factors:

- Application Requirements: Identify the specific needs of your process.

- Material Quality: Ensure the saddles meet industry standards.

- Supplier Expertise: Work with a reputable manufacturer like SKJ Group for reliable products and support.

- Customization Options: Opt for solutions tailored to your unique challenges.

FAQs

Q1. What sizes are ceramic saddles available in?

Ceramic saddles come in various sizes to suit different applications, typically ranging from 1/2 inch to 3 inches in diameter.

Q2. Can ceramic saddles be used in high-temperature environments?

Yes, their excellent thermal stability makes them ideal for applications with extreme temperatures.

Q3. Why are ceramic saddles better than other packing materials?

Their superior chemical resistance, high mechanical strength, and efficient design give them an edge over other materials like metal or plastic packing.

Elevate Your Processes with SKJ Group

Ready to experience the benefits of high-quality ceramic saddles? Partner with SKJ Group—a trusted name in the industry as a ceramic saddles supplier, and exporter. Explore our range of products and find the perfect solution for your industrial needs. Contact us today to learn more or request a quote.

Conclusion

Ceramic saddles are a cornerstone of efficient industrial processes, offering unmatched performance in mass transfer, chemical resistance, and durability. By choosing a reliable partner like SKJ Group, you ensure top-notch products and expert guidance tailored to your unique requirements. Whether you’re in chemical processing, oil refining, or environmental management, ceramic saddles are an investment in efficiency, sustainability, and long-term success.